Hand tools and power tools

Hi everyone! Thanks for coming back & welcome to DIY woodworking India once again. I will discuss about necessary tools to have for woodworking in a comfortable way. Though working with hand tools at the beginning is a good idea, it is always better to to know how to operate woodworking power tools. There are a lot of power tools available in the market, both online and local hardware shops now-a-days and you should be able to choose the right ones necessary to get the job done. DIY woodworking India will guide you to choose ones necessary for you.

Basic hand tools:

Hammer

Chisel

hand Saw

File(rasps)

Screw driver

Plier

Try square

G clamp

Measure Tape

Sandpaper

Power tools:

Circular saw

Jig saw

Drill kit

Router

Personal experience shared by DIY woodworking India

Now, I will discuss about choosing the right power tools among the available ones. I will suggest you the smartest deal where price is reasonable without compromising with the quality.

Circular saw - Always go for a good brand. They are more reliable. I will suggest Black & Decker 7 inch 1500 Watt. I have been using it for close to 3 years now and never faced an issue. It has a solid make. It can be tilted to have angular cut as well. So, cutting 45 degree angle is not a problem. It comes with necessary spanners(2 numbers) to remove/fitting/tilting blade. It has all safety measures. I personally like the bosch/skil products as well but the local hardware shop guy told me that their after sale service of is poor. But as we will not be using the power tools heavily all day long, the chances of malfunction/periodic maintenance of the product is less and hence you can opt for these products as well.

There is another choice for you i.e.; 4 inch 1200 watt marble cutter(bosch). As it is smaller in size and lighter, it may be more comfortable for you. Decide what type of wood you will be dealing with. If the wood you will be cutting is more than 2 inch in thickness, then go for 7 inch circular saw, otherwise, 4 inch is fine.

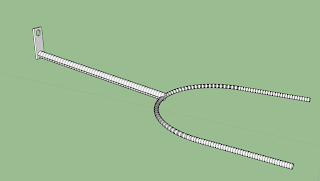

Jig saw - The reason for having jig saw is when you have to cut in a curve line for example a circle. As I said earlier, go for the branded one. Go for black and decker 450 watt product. I have this product and no complain so far. The package comes with a blade. You can buy blades of different thickness. This tool is very simple to operate. You can compare it with a sewing machine.

Drill kit - DIY woodworking India suggests Bosch GSB 10 RE. It is a complete package! This kit comes with drill machine, HSS, wood, metal drill bits, hammer, plier, measuring tape, spirit level, screw driver bits, spanner bits etc. I would suggest even if you do not want to do it woodworking, keep this kit at your home because it is so much useful in day to day maintenance work - such as drilling a hole in wall for wall mounting, hammering a nail, measuring your dining table length, unscrew a tightened screw etc. I have this product and there is no problem with this kit.

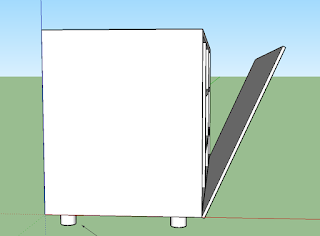

Router - It is used to hollow out a part from the wood face. For dado cut, round over and beading router is extensively used now a days. I have the black and decker plunge router 2400 watt. It is heavy duty and bulky and initially, I faced lot of difficulty in operating it. But, after a couple of days of using, you will get used to it.

Online links to buy - suggested by DIY woodworking India

Links will follow soon.

Thanks,

Sarang