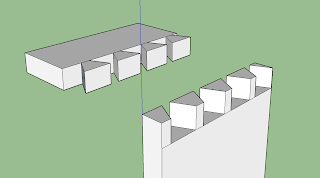

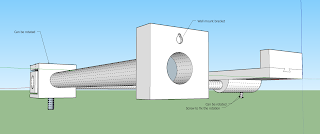

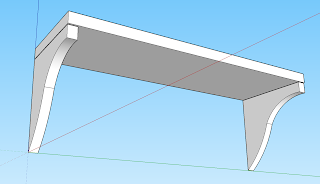

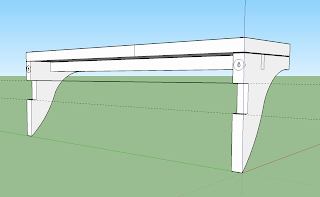

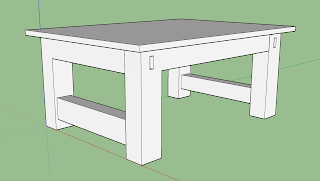

Most of today's wooden window and door frame are celebrating the strength of mortise and tenon joint. In woodworking classes back in 2003-2004 which was part of engineering syllabus, this was the first thing which was taught to us. I could not understand at that time why they were teaching this particular joint, but today I realise the significance of it. Truly amazing, isn't it? When we talk about quality woodworking, mortise and tenon is a must. Look around, if you have a wooden bed, table etc, you will spot the joint for sure.

You need not go away. Right above our feet, the ankle joint, is nothing but a mortise and tenon joint. Imagine our legs are carrying all the load of our body mass! Below is a picture of the same. Photo courtesy internet.

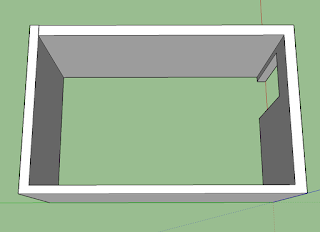

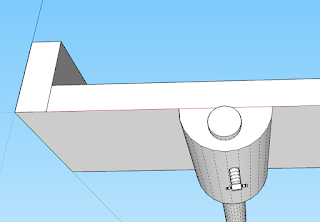

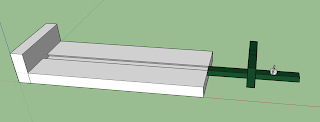

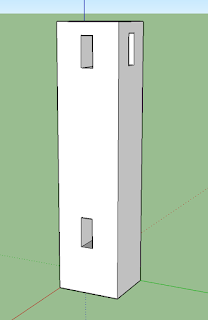

So, by now, you have understood the value of it. Now, we will discuss how to cut a mortise and tenon in wood.

I prefer to make the mortise first because it is little tougher than tenon. Based on the dimension of the mortise, we can make the tenon and fine tune it. Stay tuned for further update.

You need not go away. Right above our feet, the ankle joint, is nothing but a mortise and tenon joint. Imagine our legs are carrying all the load of our body mass! Below is a picture of the same. Photo courtesy internet.

So, by now, you have understood the value of it. Now, we will discuss how to cut a mortise and tenon in wood.

I prefer to make the mortise first because it is little tougher than tenon. Based on the dimension of the mortise, we can make the tenon and fine tune it. Stay tuned for further update.